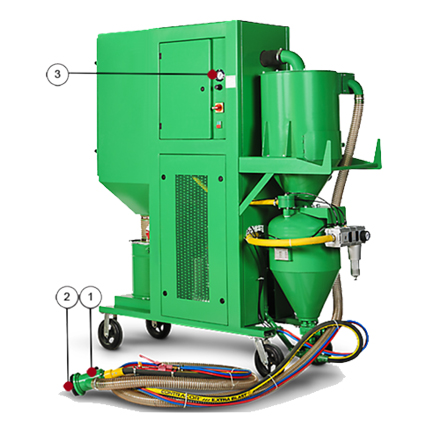

BRS Blast Recovery System (Closed Circuit)

The BRS Blast Recovery System is an electrically operated, pressure-feed closed-circuit blast machine, which can be used where open-air blasting is prohibited, or is not possible or practical. Blasting and simultaneous media recovery are initiated by pulling the DMH handle. Keeping the blast area clean allows the operator to blast without the need to encapsulate the area or wear respiratory protective equipment.

Application

Closed-circuit abrasive blast cleaning, ideal for indoor blasting where dust and abrasive contaminants should be avoided, for the blasting of welding seams and for spot repairs. Used blast media are recyclable non-metallic media: glass bead, aluminum oxide (corundum).

Standard Delivery

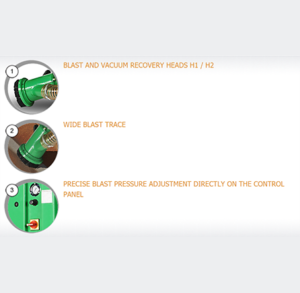

BRS systems are mounted on the portable frame and include a cyclone dust separator and media reclaimer, a dust collector with a cartridge filter and automatic pulse jet filter cleaning, a fully pneumatic remote control and blast pressure control, an adjustment device and a compressed-air moisture filter. The BRS system includes a combined blast and vacuum head, fitted with a nylon-bristle brush that presses against the blast surface. The BRS recovery head assembly comprises a blast nozzle and a vacuum hose, which evacuates dust and the rebounding abrasive following its contact with the blast surface. This BRS recovery head contains the abrasive and keeos the surroundina area clean. DMH handle.

Functional Characteristics

– portable design

– electrically driven powerful vacuum

– dust cyclone separator with removable screen

– dust collector with cartridge filter

– pulse jet filter cleaning with timer control

– adjustable blasting pressure

– compressed air filter /moisture separator

Discover superior blast recovery with BRS Blast Recovery System (Closed Circuit). Maximize efficiency, minimize waste. Explore advanced closed-circuit blasting solutions now! For more details click here