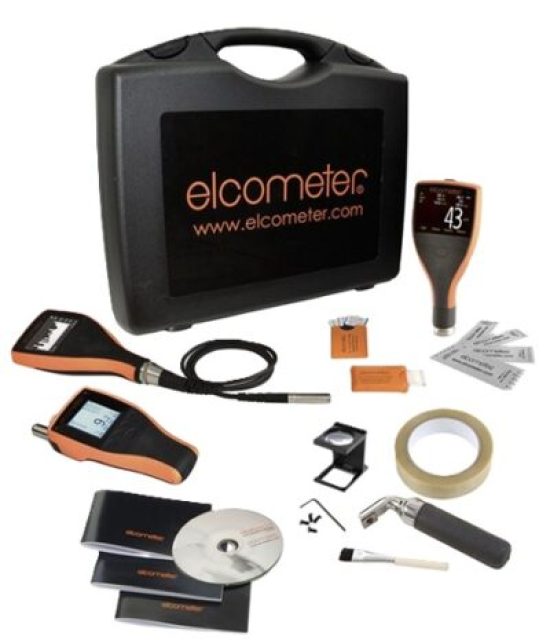

Coating inspection is a quality control process to ensure protective coatings are applied correctly and meet specifications for durability and performance. It involves inspecting both the surface preparation and the coating application itself, using specialized tools and test methods to check for defects, proper thickness, and adhesion. This evaluation is critical to prevent premature failure and ensure the structure is properly protected against corrosion and other damage.

Key aspects of coating inspection

- Surface preparation: Ensuring the surface is clean and properly prepared (e.g., via solvent cleaning or blast cleaning) before the coating is applied is crucial. Inspectors check for contaminants like oil, water, and soluble salts that can cause future coating failure.

- Application monitoring: A coating inspector observes the application process to make sure it follows the project’s specifications and uses the correct equipment and techniques.

- Coating thickness: Measuring the wet and dry film thickness is a key step to ensure the coating has been applied to the specified thickness for proper protection.

- Defect detection: Inspectors look for visual defects like cracks, bubbles, and other imperfections that can compromise the coating’s integrity.

- Performance testing: Various tests are performed to verify the coating’s properties, such as adhesion, hardness, and corrosion resistance.

- Ambient conditions: Monitoring environmental factors like temperature and humidity during the application is important for a successful coating job.

PLEASE REFER PDF ATTACHMENT FOR MORE DETAILS

WRITE US OR CALL US IF THE PRODUCT YOU ARE LOOKING IS NOT LISTED

Download PDF

Download PDF